What factors affect the work of led driver?

What factors affect the work of led driver?

From: www.hzleddriver.com

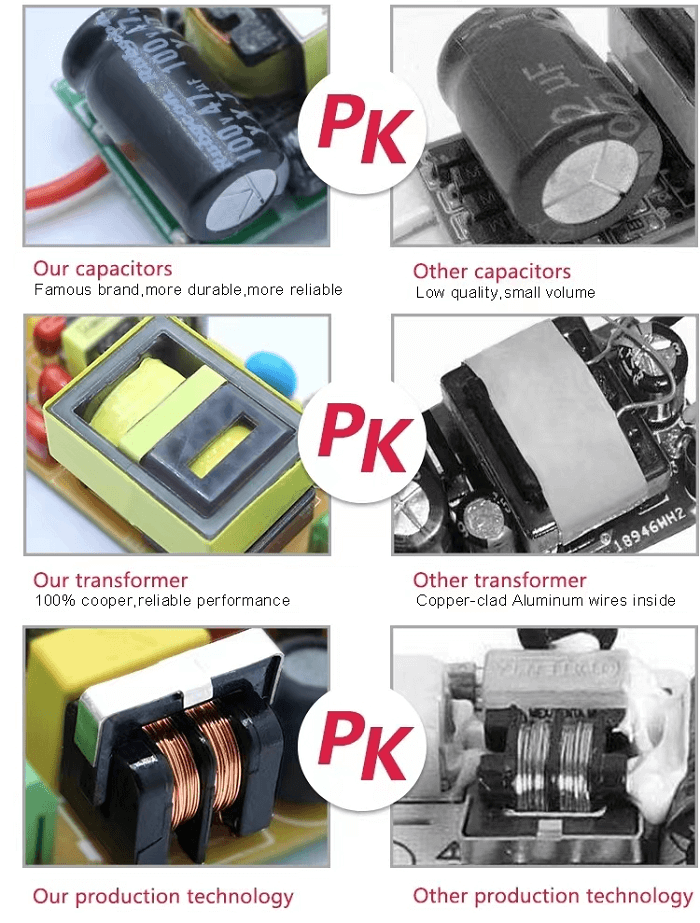

With the development of the LED industry, LEDs of high energy saving, long life, and superior performance of environmental protection have been widely recognized, and LED drivers are more and more widely used. But there is the various led driver power supply on the market, so how do we test LED drivers, and how to distinguish the quality of LED power supply?First of all, we need to know what the most important parts of a led driver are:

1) The core of the LED light driver is IC, the quality of IC directly affects the whole LED light driver.

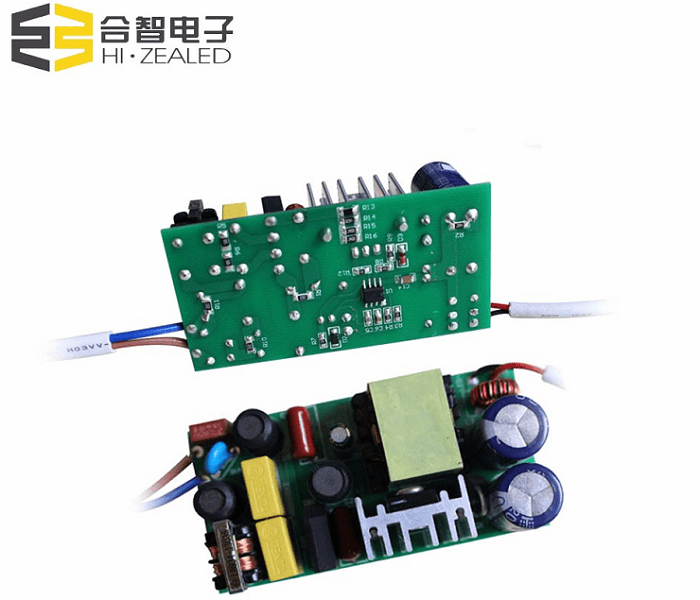

2) led power supply circuit diagram design and welding process for power supply products, such as component layout, bright and straight solder joints.

3) Transformer -- determine power and temperature resistance, such as whether the coillead is broken or unwelded, whether the insulation material is scorched, whether the iron core fastening screw is loose, whether the silicon steel sheet is corroded, whether the winding coil is exposed, etc.

4) Electrolytic capacitors and chip ceramic capacitors -- the life of the capacitor greatly determines the life of the LED power supply. (This content is also mentioned in The previous article about The main factors affecting The Life of LED drivers).

5) Whether it has been aged by high-temperature test because the incoming inspection of components is difficult to control. The aging test can screen out random failure such as false welding, missing welding, and bump, and filter out the early failure of components, so whether the power supply has been an aging test is a very important quality evaluation standard.

Aging test

评论

发表评论